In Age Industry is the leading air knife drying manufacturer in Mumbai, India. An air knife dryer or blower has an excellent technique to get rid of moisture and keep the surfaces or products completely dry. A lightning-fast stream of air is pointed at the item or surface and this blows off all the water and other liquids that are on it. This approach is useful in a variety of industries. The primary ones out of them are electronics, food processing and manufacturing. These technological devices are very efficient because they dry things very fast and do not require any physical touch to the product or surface. This makes sure that the product or surface remains intact and nullifies the chances of contamination

In Age Industry is a top-notch air knife drying supplier in Mumbai, India. You can buy Republic USA - Air Knife, Republic USA - Centrifugal Blower, Republic USA - Regen Blower, StreamTEK USA - Ionizing Air Knife, and Vortec USA - Ionizing Air Knife. Each air knife and blower has distinct features and characteristics that draw them apart from the air knife dryers and blowers of other companies.

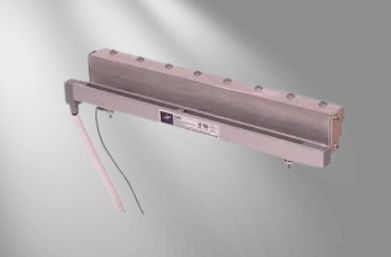

1.Republic USA: Air Knife

In Age Industry is a credible air knife drying supplier in Mumbai, India. Republic USA is a prominent name in air knife technology. Their air knives offer the best alternative to dry and clean surfaces and goods in a number of sectors. These air knives are designed in such a manner that they provide high velocity and consistent airflow. This aspect successfully eliminates humidity, waste materials and pollutants from the surface without the need to touch them.

Features

- High EfficiencyAir knives offer powerful, focused airflow that conveniently removes dampness and contaminants. This increased velocity promotes fast drying or cleaning. The structure of air knives guarantees uniform airflow distribution across the surface. This feature also decreases the processing time since the moisture is out quickly.

- Energy EfficientThis air knife provides air pattern modifications. Moreover, the velocity of the air knife can also be adjusted. Due to this reason, it saves energy costs because the air knife uses the exact amount of velocity and speed that is required for the surface or the product.

- Durable ConstructionAir knives are manufactured from tough materials, like stainless steel, aluminum, or high-strength polymers. These materials display resistance to rust, crashes, and scratches, ensuring that the air knives can endure adverse environments. Its welded construction minimizes the chance of leaks and boosts the stability of the product.

2.Republic USA, Centrifugal Blower

In Age Industry is an efficient air knife drying supplier in Mumbai, India. The centrifugal air blower can be the best option to get rid of moisture and dry objects or surfaces in fields like food processing and manufacturing. It ensures that the industrial ventilation systems have good airflow by providing proper air movement. It helps in the machine’s temperature maintenance and avoids overheating. It also assists in keeping the surface or product contaminant-free.

Features

- High Airflow The centrifugal blower has a rotational design, which speeds up the flow of air. This creates massive quantities of air. The blower can be set up in more than one stage, which improves the total airflow capacity. There is more air pressure and capacity at the end of each step. The propeller blades' form and angle are perfectly designed to increase airflow while reducing turbulence, which causes an effective flow of air.

- High PressureThe blower’s spinning function converts mechanical energy into kinetic energy. Consequently, air flows under a lot of pressure. This is an excellent method for settings like duct systems. It keeps the pressure high and reduces friction and turbulence. The air's speed and pressure remain steady as it leaves the blower. The motors in the blower have varying speeds, which lets the user change the speed based on the movement and pressure needed. Therefore, a single blower can be used for a wide range of tasks.

- Low MaintenanceThe blower has fewer parts when compared to other types of equipment. Therefore, the possibility of a technical breakdown is lower. The wear and tear is less severe as well. High-quality materials are used to make it so it can handle rough conditions. Due to this reason, the tools last longer. The sealed bearings don't need much or any lubrication. This removes the necessity of the need for routine maintenance and checks that come with open bearings. The blower's design lets it clean itself while it's running. So dust and other particles don't build up and slow it down.

- Quiet OperationThe shape of the turbine is made in such a way that it lowers the noise level. The blower has smooth, curved blades that help keep noise and turbulence to low levels while they're working. The rotors are properly adjusted and make less noise and shake less. They don't vibrate as much, which helps them run more quietly and makes them the best substitute for places where noise is a concern. The blowers can be placed inside enclosures that help keep the noise down. These areas soak up sound and make noise not as much of a problem.

3.Republic USA: Regen Blower

In Age Industry is a trustworthy air knife drying manufacturer in Mumbai, India. Republic USA's Regan blowers are a wonderful decision for businesses that want to move air in a reliable and low-maintenance way. They can be used in many different ways and they operate without making much noise. They are ideal for many industries because they increase productivity and lower maintenance and operational costs. They provide the fish farming and aquaponics systems with the optimum air flow. The wastewater treatment plants also use them for better flow of air and mixing procedures. They also provide help with better moving and handling of packing goods through better collection and transfer of dust and other debris in industrial areas.

- Custom SolutionsThe performance parameters for every industry are different. Even in the same industry, the product or the surface that needs the blower can vary. Therefore, the blowers are designed in such a manner that they can fit the needs of your particular machine, product or surface. If the model still does not fulfill your needs, we tailor the blower in such a manner that the size and configuration are the best fit for you. We make sure that they integrate in a seamless manner with your existing equipment and infrastructure so that it can minimize disruption and maximize efficiency.

- InnovationIn Age Industry is a famous Regan blower supplier in Mumbai because it focuses a lot on innovation and new ideas. We have partnered with the Republic USA and have regular meetings with them. We also discuss with our clients and acquire knowledge about the challenges that our clients face. We make the necessary changes in the blower so that the efficiency of the product can be increased. We keep a constant eye on the technological changes in various industries where regan blowers are used and make sure that our product can adapt to these changes.

- High QualityThe product has strong materials like stainless steel and high-grade aluminum. These materials don't rust, wear out, or get overheated. There are defensive layers on the model that make it more resistant to strong chemicals and surroundings. Advanced manufacturing methods and strict guidelines make sure that all the parts fit together correctly. They lower noise and vibrations and increase efficiency. Special care is taken to reduce shocks. The machine is designed to run smoothly and protect parts from damage. Thorough tests are done on every part to make sure it meets and even beats performance standards related to airflow rates and pressure capabilities.

- Expert SupportOur experts help customers figure out which blower model and setup will work best for their needs by analyzing the distinctive demands of every application. We provide complete help on product use. We help to install the product perfectly in the environment. We also make the customer aware of the safety guidelines to make sure that the blowers are installed correctly and work in a perfectly good condition for a long time. We have regular training sessions for the workers and maintenance staff. This initiates quick repairs and minor issue resolution, which reduces downtime and increases productivity.

4.StreamTEK USA: Ionizing Air Knife

In Age Industry is a knowledgeable air knife drying supplier in Mumbai, India. The air knife has an ionization unit that turns air into ions. They are positively and negatively charged particles. Surfaces with these ions don't have any static electricity. The air knife sends a stream of charged air at the target area at high speed. This not only gets rid of static electricity, but it also helps dry or clean the area well. These air knives are used in assembly lines of electronic manufacturing units, printing companies, packaging businesses, food processing facilities, automotive factories and the aerospace industry.

Features

- General Industrial ApplicationsIonizing air knives are very important in many industries. They are used to neutralize static electricity on circuit boards and components. They also aid in the elimination of static cling on printed materials. They dry inks and coatings on packaging materials. They reduce static on plastic films and containers and prevent food production lines from jamming. They are useful in the preparation of surfaces for painting or coating through the removal of static and moisture. They reduce static cling and dry fabrics fast in textile production lines. They don't need to be in direct contact with the product, which makes them perfect for sensitive uses and improves productivity and quality in the above production and processing settings.

- CleanroomsThe ionizing air knives get rid of static charges on the surfaces. This is very important in cleanrooms where static can attract dust and other contaminants. There is a sensitive electrical parts and materials’ damage prevention because it stops electrostatic discharge (ESD). The charged wind helps keep surfaces and equipment clean because it avoids the buildup of dust. It lowers the chance of dust contamination and keeps the area clean. The air knives do not have a direct touch to the surface or product. Therefore, they do not introduce particles when they're handled, which makes them perfect for use in cleanrooms.

- PlasticsThere is a lot of static electricity in plastics. This can bring in dust and other dirt. Ionizing air knives gets rid of static electricity, which keeps things from going wrong while they are being handled or processed. The static energy is removed and makes production less likely to have problems like parts sticking together or getting stuck. The ionizing air knife can be employed to get plastic surfaces ready for painting, sealing, or joining by getting rid of dust and moisture and balancing out static charges. Paints, glue, and coats stick better to surfaces that have been properly treated. This results in better finishing.

- Electronics ManufacturingIonizing air knives help make electronics more reliable and effective. They keep the products clean and free of static electricity and other impurities. This leads to fewer mistakes and better goods and increases client satisfaction. It also lowers operational expenses. It benefits the drying and cleaning process, makes it faster and in fact raises total output. Many electrotonic manufacturing units have to follow strict quality rules and safety guidelines. Ionizing air knives help these organizations meet these standards.

5.Vortec USA Ionizing Air knife

In Age Industry is an expert air knife manufacturer in Mumbai, India. A high-speed air flow and ionization work together in an ionized air knife to remove static electricity from objects while drying or cleaning them at the same time. It has a nozzle that sends a stream of charged air at a surface, getting rid of dust and moisture effectively. It releases positive and negative ions to cancel out static charges. This stops dust from sticking to surfaces and keeps sensitive parts safe to handle. It makes a focused, fast-moving air stream that can quickly cover big areas which is useful for cleaning and drying. It lets users change the amount of airflow and ions they produce. Therefore, the operation can be tailored to their needs. It works without touching the surface directly, so it does not damage delicate surfaces. This makes it perfect for use in situations that require extreme care.

Features

- High-Performance AirflowHigh velocity and ionization work together to make drying happen quickly, which cuts down on production times in areas like manufacturing, packing, and surface treatment. The strong wind makes sure that surfaces are completely dry, leaving no moisture behind. This is very important for processes that need clean, dry surfaces. The power of the airflow moves dust, dirt, and particles around and takes them away and keep surfaces clean and contamination free. It lowers the chance of defects that result from contaminants and the need for additional maintenance.

- Versatile ApplicationsIonizing air knives are useful instruments that can be deployed in many fields because they are good at controlling static electricity, drying things out, and cleaning. The Static Charge Control gets rid of static electricity in the following:

- Circuit boards of electrical components

- Plastic parts of plastic manufacturing units

- Printed materials and packaging films of the printing industry

- Packaging materials of food and beverage equipment

- Cleanrooms of the pharmaceutical industry

- Fabric cling of textile production lines.

- Easy InstallationIonizing air knives come partly or fully assembled. This makes them easier to set up. They have hooks that can be adjusted so that they can be attached quickly and easily to a variety of surfaces or structures. They are lightweight and easy to move and place without having to do a lot of heavy pulling or complicated wiring. We use standard fittings to get air, which makes it easy to connect them to existing lines of compressed air. The electrical connections are easy and can be put in quickly. They have clear labels to help workers figure out how to use them. Basic tools like wrenches and screwdrivers are all that's needed for installation.

Why is In Age Industry the most professional air knife drying manufacturer in Mumbai, India?

In age Industry is an accomplished name in the field of static electricity elimination domain. We have a comprehensive understanding of air knife and air blower technology. We are well versed with details about how it can be used in many different fields. We hire engineers and staff members who are very good at performing their tasks and are passionate about quality and innovative concepts. We use superior quality of materials to ensure that our products last for a long time and work well. We can design the equipment as per the specifications of each client and improve their performance and efficiency. We put a lot of effort into research and development (R&D) and continually updating our products to make sure that they are aligned with the latest technological advances.