In Age Industry is a leading innovative compressed air products supplier in Mumbai, India. We have the best equipment that provides the best alternative for various industries, factories, and facilities that require compressive air requirements. We cater to manufacturing companies, industrial sectors, agriculture, construction sites, and automation-related organizations. Our tools provide pressurized air and liquid to the tools and equipment of these industries and make sure that the production system and processes run smoothly and without any hassles or issues.

In Age Industry is a top-class innovative compressed air products manufacturer in Mumbai, India. We have joined hands with Vortex USA, which is known for its excellence in creating air pressure-related and liquid spraying products. They are extremely sturdy and durable.

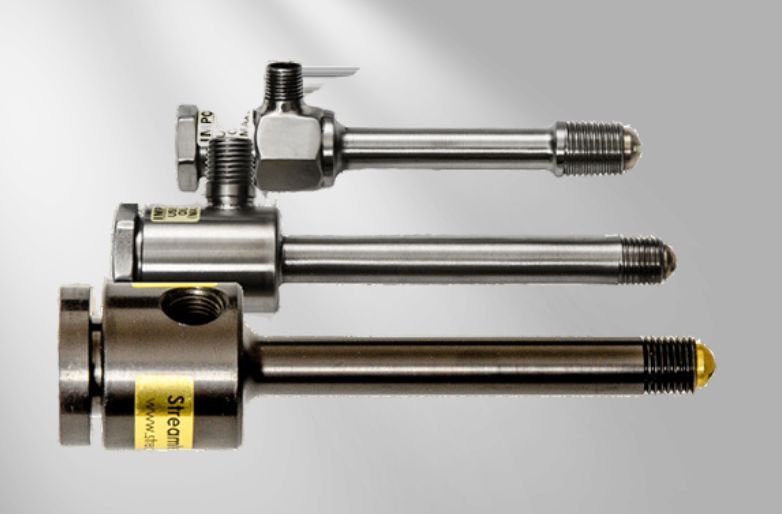

1.Vortex Tube: StreamTek / Vortec USA

In Age Industry is a credible innovative compressed air products manufacturer in Mumbai, India. A vortex tube uses fluid dynamics to split a compressed gas stream into two temperature streams. One of them is hot, and the other one is cold. In the vortex tube, gas is quickly spun within a cylindrical container to form a spiral vortex that causes a temperature variation. It is often used to cool small spaces or specific components like cooling tools, machinery, or electric components. It is also helpful to cool isolated sites where conventional refrigeration systems are not feasible. It is effective for limited temperature control analyses, such as material testing under regulated temperatures. It is occasionally used for air cooling in pneumatic systems to maintain equipment operating temperatures.

Features

- Maintenance-free, with no moving parts:TThe Vortex tube has a basic cylindrical structure with a circular opening and two outlets. Out of which one is for hot gas and the other is for the cold one. Along with that, it has an adjustable valve. The maintenance of these components is easy and quick. Moreover, it does not have any working parts like fans and motors, which are present in refrigeration units or air conditioners. These parts have to be maintained on a regular basis. Since there is no such part in the Vortex tube, the maintenance is low.

- No electricity required at the cooling site:The cooling or heating action of the vortex tube comes from compressed air or compressed gas. It doesn't need an outside power source like fuel or energy. The spinning of the compressed gas in the vortex tube has a mechanical effect on the whole process. There are no electrical parts like fans, motors, or compressors in the tube that might require electricity or any other fuel to function. Compressed air is the only source of energy that is required. The tube completes all its operational activities with this gas and does not need any other source of energy.

- Cools without refrigerants, as low as -40°F:Compressed air, usually at a pressure of 60 to 150 psi (pounds per square inch), flows through the vortex tube. The exact pressure depends on the task at hand. The air is introduced into the vortex tube from the side, which makes it spin quickly inside the cylinder-shaped chamber. The force of centrifugal motion splits the compressed air into two streams, one hot and one cold. Under ideal conditions, the cold stream can get as cold as -40°F (-40°C). This depends on how fast and how much pressure is there in the compressed air.

2. Cold air gun StreamTek / Vortec USA

In Age Industry is a reputed innovative compressed air products manufacturer in Mumbai, India. A cold air gun is a special kind of tool used to cool an area or part. It sends a stream of very cold air through it. These guns are often used in factories, especially to cool things that need to be cooled precisely, like electronics, tools, or machines. A temperature difference is made by compressed air in this technology. Cool air comes out of one end of the gun, and hot air comes out of the other. Most cold-air guns are small, light, and easy to carry. Because of this, they are easy to add to a lot of different desks or places in manufacturing, drilling, and other industrial processes. They are easy to move and set up anywhere localized cooling is needed because they don't need any power sources other than compressed air.

- Sub-freezing air as low as -30°F: Cold air guns generate air that is below freezing, with temperatures as low as -30°F (-34°C), though it depends on the type and the environment. These guns cool things down using compressed air and vortex tube technology. This makes them very useful for cooling in specific locations like machining, electronic cooling, and spot cooling. They can reach temperatures below freezing without using refrigerants. They are also eco-friendly and work well for precise cooling.

- No moving parts: The nozzle of the cold air gun is adjustable, which helps to direct the cold air speed and amount more accurately. However, it is just a narrow opening where the cold air stream from the vortex tube can come out. These parts don't move at all. The system only depends on the pressure of the compressed air coming in and how the vortex moves as a result. Since there are no movable parts, the design is simple and easy to integrate. There are no complex movable parts, which makes the equipment last long and without major maintenance needs.

- Outperforms mist coolants: A cold air gun outperforms mist coolants on a number of parameters, which are under:

- Cooling efficiency:The air gun can cool the area better. In fact, it has the potential of subfreezing up to -50°F. The cooling of a mist coolant depends on the air flow and volume, which is less effective than the compressed air technology.

- Wear and tear:There are no complex parts and movable parts in a cold air gun, which means that there is no friction between the parts. This leads to less wear and tear on the components.

- Energy consumption: The air gun consumes energy that is only required to compress air. On the other hand, mist coolers require more energy to cool pumps, atomizers, and coolant fluid.

- Maintenance: The cold air gun has fewer maintenance needs because there is no lubrication requirement or any complex and movable component. However, the mist coolants have nozzles and other components that can clog and require regular cleaning. Its parts also have to be lubricated from time to time.

3. Air flow amplifier StreamTek / Vortec USA

In Age Industry is a notable compressed air products supplier in Mumbai, India. An air flow amplifier is also called an air amplifier or venturi air amplifier. It boosts the flow of air or air pressure in a system through the use of compressed air as a source. It functions as per the Venturi effect. The air moves faster through a narrow space, which makes a lower pressure that pulls in air from around it. Based on this concept, the amplifier can boost the flow of air while still using a small amount of power. They are used to cool a number of products through a high volume of air. They can be used to cool down tools for CNC or cutting work. They work very well in pick-and-place tasks and make a vacuum. It makes a stream of increased air, which can move light things or clean up areas. Many textiles use it in manufacturing, printing, and food processing.

- Amplify compressed air volumes by 12 – 20 fold in ducted applications: The air flow amplifier is designed in such a manner that they can increase the compressed air volume in a ducted application. In fact, the volume of air rises 12 to 20 times. The operation of the device enters ambient air. This air combines with a small amount of compressed air and creates a high velocity and high volume output. The amplified airflow is the best tool to cool ventilate. They can also convey materials easily. The amplifier, because of its high air volume, can perform extremely well in industrial applications where it is critical to have constant air movement.

- Adjustable airflow and output: This air flow amplifier has the feature of adjustment of airflow and output. Due to this reason, it is possible to have complete control over the volume of air and its velocity. Users can adjust the air as per their specific needs and the requirements of their equipment and particular area. There is also air gap adjustment possible, which helps to maintain the perfect output force and flow rate. Due to this ability, this amplifier can meet high standards and parameters of various industrial settings. It also plays a role in making sure that the machine works effectively and productively.

- Quiet: meets OSHA noise requirements: TAs per the OSHA noise requirement, the sound level should be below 85 dB over an 8-hour shift. This amplifier follows this parameter. There is very little noise in this amplifier because the internal channels and air flow part are designed in such a manner that they cause minimum noise. The nozzels are also smooth and have a laminar flow, which is better than regular turbulent flow to keep the sound levels in check. There is a special coating and sound-reducing materials that do not let the noise levels go high. In short, even though the velocity of air pressure is greater, the design ascertains that the amount of noise created is at the bare minimum.

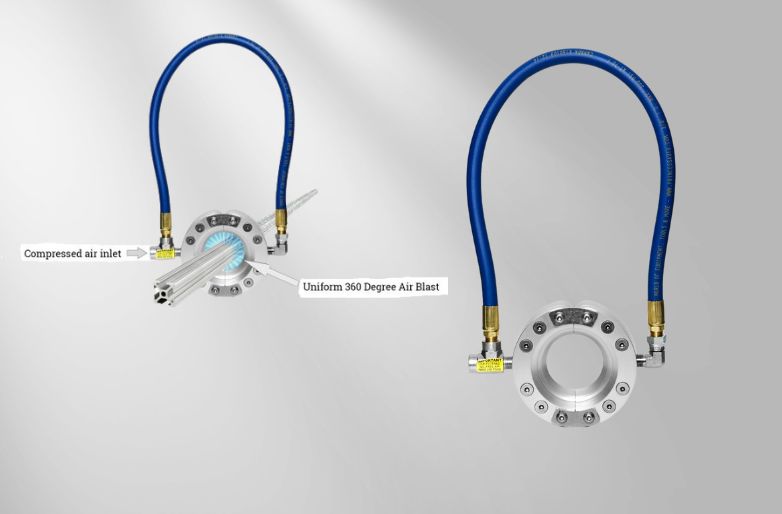

4. Air Wipes: StreamTek USA

In Age Industry is an experienced innovative air products manufacturer in Mumbai, India. Air wipes are a very important part of manufacturing and processing. They have the ability to direct a high-velocity stream of air around the product, which gets rid of the moisture, debris, or dust around it. The best part is that there is no physical contact with the product, which does not harm the product in any way. The use of durable materials like aluminum and stainless steel helps the product to last long for a large period of time. They are commonly used in industries that are related to cable and wire manufacturing, extrusion, and coating.

- Dryes tubes, wires, and fibers: The air wipes are manufactured to dry and clean round or cylindrical items like tubes, wires, hoses, and fibers. They can work in an effective manner on various production lines where these items are manufactured. They are durable and can create a perfect ring of compressed air around the product. They are the best option for fibers because they remove the moisture and dirt from them without physical contact. This keeps the delicate fibers, tubes, and coated wires intact. There is a uniform flow of air in all the parts of fibers, which makes sure that these items are completely free from moisture and dust.

- Removing excess water and oil: Air wipes are highly efficient tools to remove excess water and other liquids in the items while they move through production lines. The high volume and speed of air are able to ensure that the products are completely dry. There is a consistent flow of air in all the parts of the product, which ensures that there are water spots and contamination due to water. It also reduces production time because the products are ready for the next process faster because of the drying and contamination removal process while still on the production line. They get rid of water after cooling baths in the cable and manufacturing industry. They can be installed in dry packaging and food materials processes. It clears liquids and oil from parts and vehicles in the automotive units.

- Uniform wiping surfacesThe uniform wiping surfaces in air wipes are made in such a way that the airflow can reach every part of the product on the production line. Any unwanted material, dust, debris, and water sticking to the item blows off. The design of the air wipe is circular, which is helpful in making sure that even cylindrical objects like cables and hoses can be cleaned effectively. The air jets are also at even places so that there is a complete 360-degree cleaning process. The nozzles and seals are of very high quality, which removes the chances of leakage and downtime because of inconsistency in air flow.

5. Cooling Vest, Vortec USA

In Age Industry is a credible innovative air products manufacturer in Mumbai, India. The cooling vest is a device that workers, athletes, and medical patients can wear to manage their body temperature. It is especially useful in factories and industries because such facilities have a very high temperature, which can lead to various health issues due to the extreme heat. Similarly, construction sites are usually outdoor, and the labourers have to work in hot sun, which can lead to heat strokes. These cooling vests can help to manage these risks and provide personal body temperature regulation to the laborer and worker.

- Improves Worker Safety: Cooling vests are one of the best ways to safely decrease the temperature of the body. In construction sites, the laborers have to work in the open where the levels of heat are very high especially in summer. The heat is more even in other seasons during 12.00 to 4.00 pm in a country like India. Similarly, industries and factories have machines that emit extreme heat, which makes it difficult for workers to work. These vests are designed to manage body temperature and reduce the risk of heat exhaustion, dehydration, and heatstroke.

- Maximizes productivity and comfort: These vests help to maintain the temperature of workers and laborers that are working in construction sites and industrial facilities. Therefore, they can work better and do not get fatigued or tired due to the extreme heat. Moreover, it prevents various heat-related issues like heat stress, dehydration, heat rash, and cardiovascular strain. It helps to maintain the production levels because the workers and laborers can work effectively even if the shift time is longer or there is a need to do overtime. It also helps to avoid mistakes and accidents because the workers can focus better. It increases production also because the workers take less leave due to health issues created by extreme heat.

- Reduces Air Conditioning Needs:Sometimes there are places in an industrial facility that, if cooled, may decrease productivity. Similarly, sometimes the work has to be done outdoors where air conditioning or cooling equipment might not be feasible. A vest is able to provide cooling to every worker individually. It removes the need to cool the entire room. It is light weight and employs the latest cooling technology. It slowly gets rid of the heat from the worker’s body and helps him or her to work efficiently. On the other hand, if an air conditioner is installed, it will be costlier and may also not be able to cover every cover of a large facility.

6. Spray Nozzles, Vortec USA

In Age Industry is a premier innovative air products supplier in Mumbai, India. The spray nozzles provide a droplet-sized spray. Due to its small size, it can easily cover more surface area than a regular nozzle. It can be directed to the exact area, which increases its efficiency. It provides evaporative cooling, atomization, humidification and wetting that is required in a number of production and manufacturing processes of food processing, automotive industry, electronic and semi conductor industry. Farmers can also use it on farms to spray herbicides, pesticides, and fertilizers on the crops.

- Controlled, ultra-fine droplet sizes: The spray nozzles have ultra-fine droplet nozzles. These nozzles ensure that the flow of water and other liquids is precise. The liquid is dispersed effectively on the surface, material, or field. It avoids the wastage of liquid. There are a number of components in a production line and even very delicate spare parts. Similarly, there might be a specific area of the product that might be affected because of water or liquids directed in these areas. A precise emission makes sure that these parts and areas are completely safe. It is the best for processes such as cooling, humidifying, coating, and dust suppression.

- Removable nozzle tips for easy cleaning and replacement: The nozzle tips of the spray nozzles are easy to maintain because they can be easily removed. Many times dust and residue materials can clog the nozzle tips. This clogging might affect the consistent flow of liquid from the nozzles. Since the nozzles are removable, their maintenance is very easy. It also increases the lifespan of the entire spray nozzle. Since the spray nozzles are easy to remove, if they do not work effectively, they can be replaced as well. This feature helps to maintain a consistent spray pattern and droplet size which is very important in various processes of food processing, pharmaceuticals, agricultere and other industries.

- Interchangeable tips for fogging, atomizing, and humidifying.:The interchangeable tips of the spray nozzles are very helpful when the same nozzle has to be used for a number of different processes in the industrial units or agricultural fields. The tips can also be customized as per the need of the special process. The spray pattern and droplet size are very easy to change. This assists in an ultrafine mist of cooling and a denser spray for coating or atomizing. This feature helps in different kinds of processes in agriculture, manufacturing, and HVAC, where each process might require a different spray size.

Conclusion

In Age Industry is a highly professional innovative compressed air products supplier in Mumbai, India. We have different departments that complete different core activities. These departments have well-qualified and highly skilled staff. All the departments are very transparent and do not hold any information from the customer. The pricing, delivery times, and any potential issues are explained in detail so that the right expectations are set. We provide complete information about the product through trainings. We also provide manuals that can help understand the workings of the product easily. This decreases downtime, and minor issues can be resolved easily. We meet the deadlines and deliver our products on the promised date.