In Age Industry is a top-class vacuum pump supplier in Mumbai, India. Our pumps are the best in the industry. They are designed in such a manner that they can fulfil the needs of different kinds of industries. They are the best alternative for the packaging industry, medical suction, printing, and HVAC systems. They can also work with complete precision in large facilities, manufacturing plants, hospitals, and laboratories. They can be operated on multiple workstations or rooms that have a large requirement of vacuum at the same time.

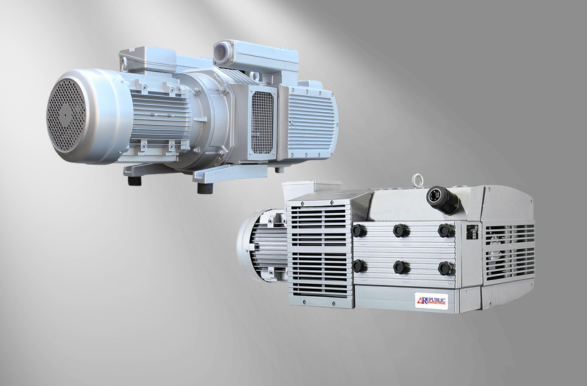

In Age Industry is a well-known vacuum pump manufacturer in Mumbai, India. We have different kinds of pumps that work well in a variety of factory setups and industrial facilities. We manufacture and supply vane pumps, claw pumps, and central vacuum pumps.

1.Republic USA Dry Rotary Vane Pumps

In Age Industry is a reputed vacuum pump supplier in Mumbai, India. The dry rotary vane pump is a device that can remain functional without the use of oil or any other lubricant. The best part of this equipment is that it is very sturdy and can work in perfect condition without the need for high maintenance. Its equipment can resolve contamination issues very well. The pump has a rotor with sliding vanes that is offset within a cylindrical case. When the rotor spins, the vane slides in the outward direction because of centrifugal force. This action compresses and traps the air as it moves through the air chambers.

- Versatile ApplicationsThe dry rotary vane pumps can be used in a number of industries and factories where hygiene, low maintenance, and environmental friendliness are high priority. Since there is no contamination due to lack of oil use, it can be used in the following:

-

- Hospitals, cleanrooms, and research laboratories for tools like sterilizers, mass spectrometers, and autoclaves.

- Food and beverage packaging production lines to for seal food items or modify atmosphere packaging through the use of vacuum

- Electronics and Semiconductor Manufacturing processes which require a contamination-free equipment production

- Manage paper positioning and transport through stable vacuum creation and avoiding soiling of the material

- Quiet OperationThe pump has an oil-free performance, which removes the chances of noise that is related to the circulation of oil and fluctuations in pressure. Similarly, the device is designed in such a manner that the vanes and rotor work effectively without causing any frictional noise. Thirdly, the materials used in the pump are not metals but have graphite and carbon, which have a natural quality of creating minimum noise. This quiet operation makes it an ideal choice for medical facilities like hospitals, research centers, and laboratories. Users and people around production lines in industries and factories can also do their work without getting disturbed due to noise and do not need any ear protection.

- Low MaintenanceThere is no need for oil or other lubricants in the pump. This characteristic of the pump removes the need for a number of maintenance functions, like the following:

- Unlike regular pumps, which require regular oil changes, these pumps do not need such a step, and the pump can work effortlessly.

- There is no oil filtration system in place, which might require the hiring of staff and time to conduct this activity

- There is no need to clean the pump regularly because there is no use of lubricant, which avoids mist, vapor, or residue that are created due to oil or other lubricants.

2.Republic USA-Claw Pumps

In Age Industry is a trusted vacuum pump supplier in Mumbai, India. The claw pumps are positive displacement pumps. They are also known as claw vacuum pumps. The name claw comes into play because it has two claw-shaped rotors that interlock against each other within a chamber. It discharges the air out through the rotor's rotation in the opposite direction. The pump is highly durable. The reason for that is its design, which does not require any kind of contact. It also does not need oil or any other lubricant to function. They can work both as a vacuum creator as well as a tool that generates low pressure.

- Versatile ApplicationsThe claw pumps are used in a variety of industries and factories because they are sturdy and operate in an effective manner. They are used in the following:

- Food and beverage industry to create vacuum sealing

- Pharma and medical sector in processes like sterilization, lab equipment operation, and medical suction

- Automative industry to pick and place automation systems

- Conveying industry for vacuum conveying of powders, pellets, or granules

- Quiet OperationThe pump has a unique design and operational technique that does not cause any mechanical noise. The pump does not cause any friction because the rotors rotate in a contactless manner. There is no use of lubricants or oil, which prevents noise due to vibration. There are also noise-decreasing materials that further decrease the chances of noise. Therefore, this pump does not cause noise and operates quietly. This function is especially useful in medical facilities like hospitals, clinics, research centers, and offices. It is also useful in factories and industries because it helps to fulfil noise compliance standards and improve focus, communication, and productivity.

- Low MaintenanceThe pump has a design wherein the rotors do not contact with each other. This minimizes wear and tear of the pump because of friction. Secondly, it does not require any kind of lubricant, which keeps the pump clean and increases its life. Moreover, it has very few moving parts, because of which there are fewer possibilities of breaking down. The materials are carefully chosen, and it is made sure that they are of excellent quality, which increases its durability. The pump has a self-cooling mechanism, which avoids the chances of damage due to extreme heat. It has various accessible parts that are easy to inspect or repair, which decreases the time and money that are utilized in maintaining the equipment.

3.Republic USA Central Vacuum Pump

In Age Industries is a reliable vacuum pump manufacturer in Mumbai, India. The central vacuum pumps are made in such a manner that they can easily create extremely low pressure in various parts of the building or facility. One central vacuum pump can fulfil the need of multiple regular pumps that have to be set up in various places of the facility. This is an essential element in applications and production lines that require a highly controlled vacuum environment at many places at the same time. Many production units of various industries and factories require such high vacuum devices to ensure the production of goods, avoiding the air particles, which are a hurdle in productivity. The industrial manufacturing processes are an example of it. Not only that, even laboratories and big houses are in need of such vacuum pumps.

- Versatile ApplicationsThese pumps are used in various processes in different industries and manufacturing units, which are as follows:

- Industrial manufacturing involves processes like material handling, dust collection, and process vacuuming.

- Cleaning of hotels, hospitals, and office buildings

- Manage sawdust and wood shavings in Woodworking shops

- Removing chemical fumes, dust, and other contaminants in laboratories

- For central cleaning in big houses

- Quiet OperationThese pumps have an advanced mechanism that has balanced rotors and high-quality bearings that do not cause any noise. Secondly, the components are designed in such a manner that they cause no frictional noise. It has a soundproof casing, which reduces the chances of noise further. The use of high-quality materials in the components helps in the soundless running of the pump. There are no moving parts, and even if there are such parts, they move at a very low speed, which decreases the possibilities of noise. There are strong mounts and brackets to install the pump, which evades sound as well.

- Low MaintenanceThe components of this pump do not contact each other, which reduces issues like wear and tear and replacement needs, which decreases the maintenance requirements. There is no lubricant use, which avoids contamination and the necessity of regular oil changes and lubricant-related maintenance demands. There are very few moving parts, which causes fewer chances of friction and issues caused on the equipment due to them. The materials are also durable enough and last for a long time without any necessity of maintenance. There are high-quality sealants in the pumps that last long and do not require frequent repairs.

Conclusion

In Age Industry is an advanced vacuum pump manufacturer in Mumbai, India. We have a long-standing collaboration with the Republic USA. We have a large variety of models to choose from. Our prices are also the best in the market. We have a customer-centric approach. Therefore, we also make changes in the pump as per your specific needs. There is a team that makes sure that every pump is of excellent quality. We carry out various tests and check the durability of our products in different environments. We provide complete customer assistance and knowledge about our products when a client buys our product. Our after-sales and maintenance and repair assistance ensures that our vacuum pump can work in an effective manner for a long period of time.